$0.00

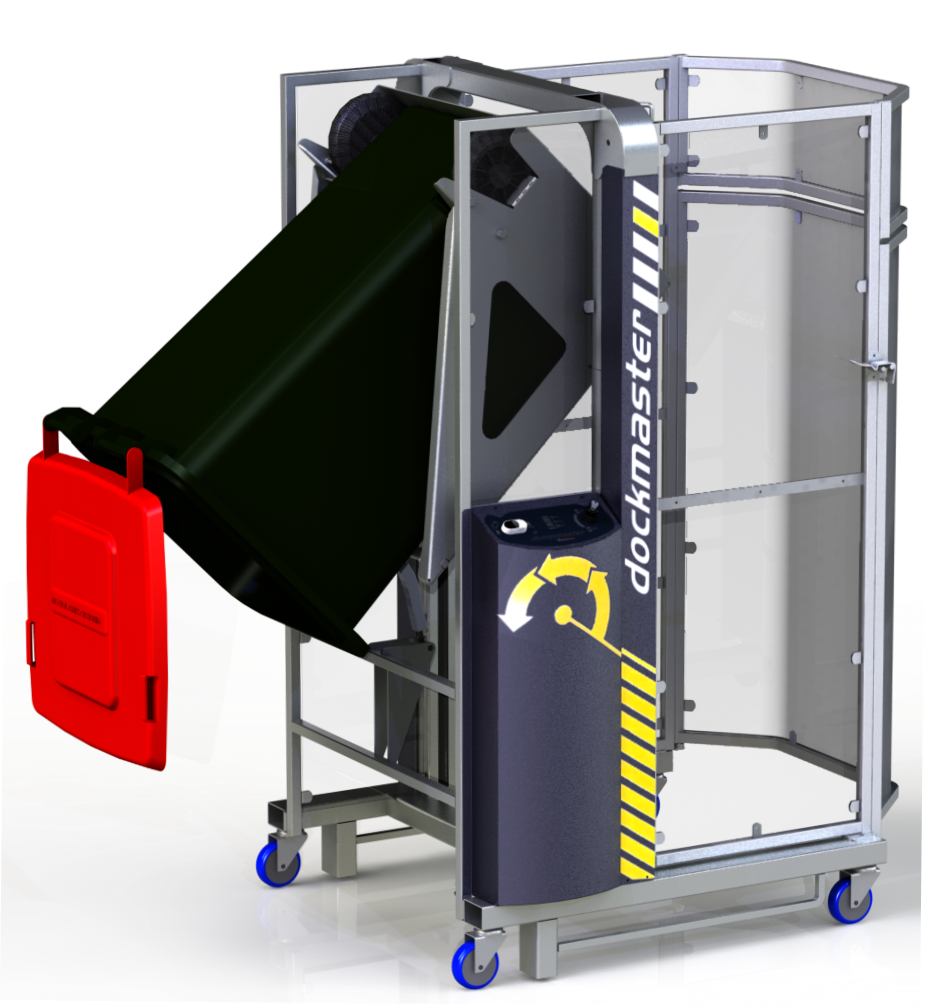

The Dockmaster was designed with a specific task in mind – safely tipping wheelie bins and drums from a raised loading dock. In many operations this is currently done by hand, which is difficult, slow and dangerous. The Dockmaster completes the process in seconds and is fully compliant with stringent new safety requirements.

The Dockmaster is based on the proven design of the Simpro Dumpmaster, but with unique features. The tipping mechanism inverts bins as low to the ground as possible, at just 700mm, while still keeping the weight within the footprint of the machine. To allow operating near platform edges the Dockmaster is fitted with safety feet, just behind the wheels. These catch the machine if it is rolled over the edge, instantly preventing further movement.

The Dockmaster is built to the same rugged specifications as the Dumpmaster, including the steel frame, powerpack and control system. It will effortlessly tip most types of wheelie bin at weights up to 250kg, and is designed to withstand many years of operation indoors or outdoors.

The Dockmaster is compatible with most Dumpmaster options and accessories, including:

| Dockmaster Specifications | |||

|---|---|---|---|

| Model (SKU) | DM0700 | MD600B0700 | MD600E0700 |

| Tipping Height (“TH”) | 700mm | ||

| Guarding Height (“GH”) | 1755mm | 2300mm | |

| Overall Height (“OH”) | 1770mm | 2355mm | 2440mm |

| Length (door closed) | 1170mm | 1342mm | 1592mm |

| Length (door open) | 1834mm | 1592mm | 1842mm |

| Width | 964mm | 1874mm | |

| Weight | ~185kg | ~286kg | ~320kg |

| Max Bin Weight | 250kg | 600kg | |

| Cradle Compatibility | 60L, 80L, 120L, 140L, 240L wheelie bins (options: custom cradle) | 660L wheelie bin (options: custom cradle) | 1100L wheelie bin (options: custom cradle) |

| Bin Throw (“BT”) | 100mm | ||

| Electrical Specifications – Battery | 2x 12v 21Ah sealed gel batteries in series configuration, driving 0.8kw DC motor drawing up to 60 Amps, with 24v DC control voltage | ||

| Electrical Specifications – Single-Phase | 240v AC 50/60hz 1-phase mains supply, driving 0.75kw AC motor drawing up to 8 Amps via VSD (Variable Speed Drive controller), with 24v DC control voltage | ||

| Electrical Specifications – Three-Phase | 400v AC 50/60hz 3-phase mains supply, driving 0.75kw AC motor drawing up to 1.9 Amps, with 24v DC control voltage | ||

| User Interface | Raise/Lower buttons, key switch, battery indicator, master lockout switch (options: E-stop button, VSD control joystick) | ||

| Ingress Protection | IP55 (options: IP56, IP69K) | ||

| Guarding | 25x25x2.5 wire mesh (options: transparent PET-G, 1.6mm sheet metal, sheet stainless steel) | 1.6mm sheet metal (options: transparent PET-G, 25x25x2.5 wire mesh, sheet stainless steel) | |

| Corrosion Protection | Hot-dip galvanised frame, galvanised cradle, zinc-plated guards (options: full or partial stainless steel) | ||

| Door | Left-hinged door (options: right-hinged door, swing-up door with gas strut assist) | Swing-up door with gas strut assist (options: left-hinged door, right-hinged door) | |

| Door Lock | Solenoid-operated electrical safety interlock | ||

| Wheels | ⌀100mm Blue Resilex castors (options: ⌀200mm castors, bolt-down lugs) | ⌀200mm Blue Resilex castors (options: ⌀100mm castors, bolt-down lugs) | |

| Applicable Standards and Certifications | AS/NZS4024, ISO 13849-1, IEC 62061, Conformité Européene (CE), EN 349 1993, EN 574 1996+A1:200, EN 953 1997, EN ISO 4413 2010, EN ISO 12100 2010, EN ISO13849-1 2006, EN ISO 13857 2008, EN 60204 2006+A1 2009, EN61000-6-2 2005, EN61000-6-4 2007, Machinery Directive 2006/42/EC, Electromagnetic Compatibility Directive 2004/108/EC | ||

**Recycled content depends on bin colour and excludes lid, wheels and axles

*minimum batch quantities required

Contact us today to conduct an audit of your municipality and advise how your council can transition to one of Australia’s most sustainable bins.